Three screw pump correct disassembly and installation steps

Three screw pump remove the right steps and matters needing attention when assembly:

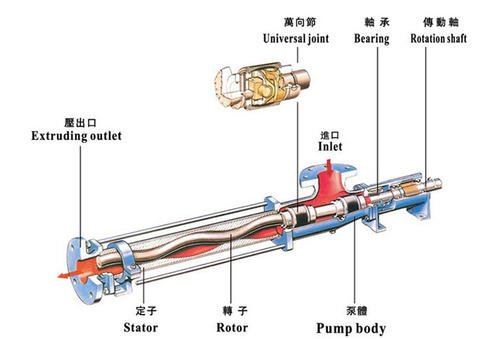

Remove the step

1. Out of the pump and motor, emptying medium (to prevent motor toxic medium hurt)

2. Remove the screw pump eduction body.

3. Remove the screw pump stator and, if necessary, press the pump shaft steering wheel do auxiliary shaft

4. Remove the rotor and intermediate shaft

5. Remove the drive shaft and the shaft seal

6. Long-term unused screw pump, to make antirust processing, into the pipe bend fractures, the oil inlet and the hot oil pump joint a tiny gap, are likely to make the air entering into the tubing.

Matters needing attention

1. When the assembly screw pump parts should be carefully cleaned, examined, the damaged parts should be replaced.

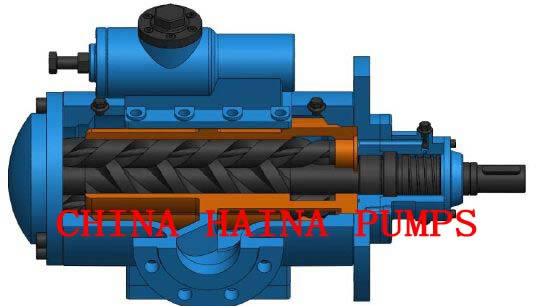

2. Two universal joint transmission shaft assembly, should check the seal for damage, free cavity filled with grease

3. The correct installation of the bearing is axis flexible rotation, no jam phenomenon.

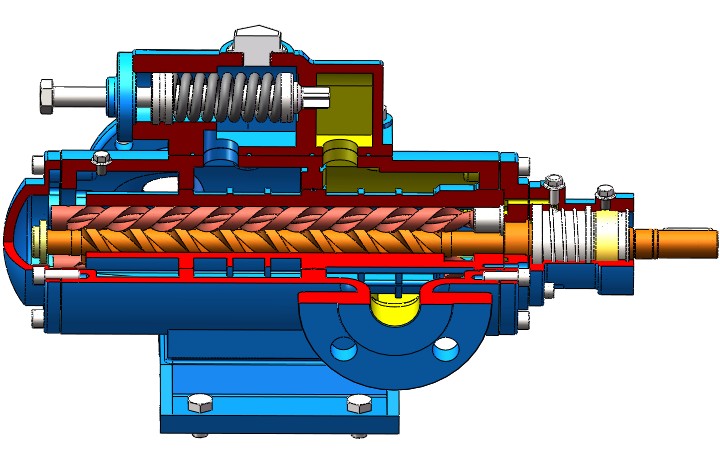

4. The shaft seal installation: stuffing box, when installation should make packing gland hold-down bolts location within the shell to install window, facilitate the wrench to adjust the bolt;

5. Tighten timing eduction body pressure, tighten nut should be uniform;

6. Mechanical seal installation should be careful, friction pair end surface should be clean and coated with grease;

7. The installation of the stator, the rotor with oil daub, stator inner cavity surface, is advantageous to the stator installation;

8. Installing a assembly, coupling installation deviation: delta Y 0.2 mm or less, delta alpha 30 or less '.

Copyright Protection: This page by Pump original,Please retain the link: /Screw-Pump/Three-screw-pump-correct-disassembly-and.html

- Previous:Screw Pump Classification

- Next:Three screw pump installation